A Helping Hand

December 9, 2014

In Oct. of 2013, Tina Maas asked Orono Technology and Engineering Instructor, Mark Vonder Haar, if he would be interested in constructing a 3D printed hand for her nephew, seven year old Johnny Skoog, who was born without four fingers on his right hand.

“I approached Mark about working with Johnny after I saw [information] about 3D printers and building hands on TV,” Maas said.

Not only is information about this community found on TV, but online as well. There are many organizations that get into contact with families who need 3D printed limbs. According to the organization E-nabling the Future, the movement to build 3D printed hands was inspired by an individual who helped to build a prosthetic hand for a young boy in Africa.

Vonder Haar readily agreed to help construct a 3D printed hand for Johnny. With the help of his technology and engineering classes, Vonder Haar completed the entire project in a year’s time.

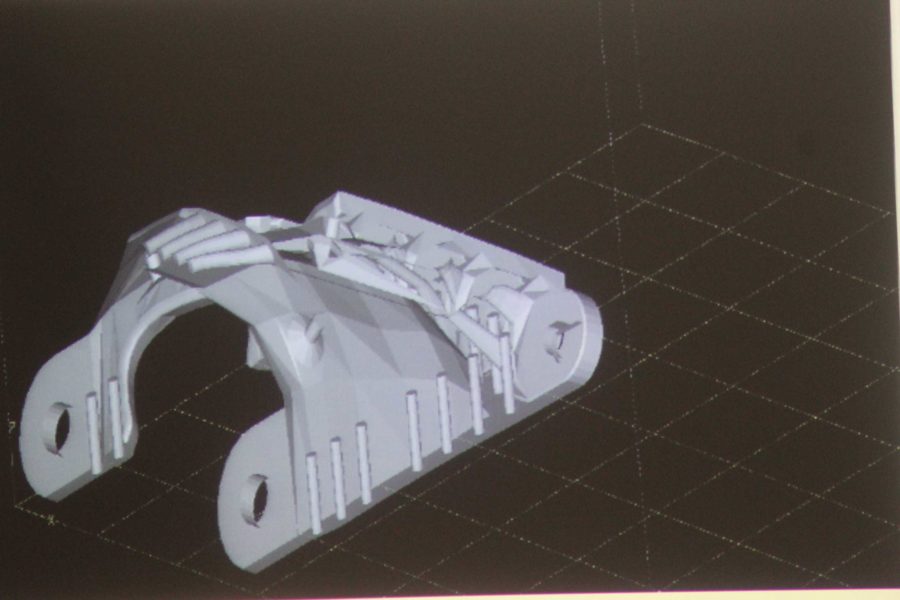

“We went through a few different hand [prototypes] before deciding on the Raptor Hand for Johnny,” Vonder Haar said.

The Raptor Hand is fastens to the wrist with the use of velcro. By bending his or her wrist, the wearer is able to move the fingers on the Raptor Hand in order to grasp objects. Compared to other 3D printed hand designs, the Raptor Hand is easy to assemble and repair as well as being a go-to design in the 3D printed hand community, according to E-nabling the Future.

Johnny’s hand was constructed by the use of 3D printed files that were assembled after their completion. According to Engergy.gov, 3D printers work by depositing a layer of material, and then continuing to layer more material on top until a form is completed.

Upon its completion, Johnny received his finished Raptor Hand in October of this year.

His aunt was overjoyed to see the final product of the work that Vonder Haar and Orono students completed. “My initial reaction was excitement,” Maas said. “Johnny may not use the hand every day, but it can give him confidence.”

This excitement continued for Johnny and his family as he began to wear and use the hand at home.

“I appreciate that someone [Mark] would take the time our of their busy schedule to work on a 3D printed hand,” Johnny’s father Adam Skoog said.

Johnny will be fitted with larger 3D printed hands as he grows. Vonder Haar is interested in continuing to work with the Skoog family, and with others to construct 3D printed hands.

“My name is out there as a contact for [helping] to make printed hands,” Vonder Haar said. “I would definitely help out others in the future.”

Numerous organizations exist in the online community of 3D printed hands. These organizations work to connect those in need of a hand with individuals willing to assist in constructing them.

For now, Johnny continues to get used to his new hand by wearing it 30 percent of the time, typically when he is at home or during the weekend. With use of his right hand, Johnny is now able to grasp items by flexing his wrist.

“I can pick-up toys and get high-fives,” Johnny said. “It makes me really happy.”